-

Posts

3,059 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by DavePilot

-

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

Admin Comments

- many of the new SCFLIER Members are considering buying a SportCruiser - vs buying a Bristell, RV-12, or other LSA...

- We have new members that are A&P/LSRM wanting to learn more about maintaining a SportCruiser

- Some of our new members recently bought a used SportCruiser

- a key fact - not all SCFLIER Members currently own a SportCruiser, and a significant percent of our new members may buy another airplane.

- a few SCFLIER Members own a “competitor airplane” to the SportCruiser LSA that uses the same ROTAX 912 engine or similar Dynon/GARMIN avionics, and join SCFLIER to learn about ROTAX/Dynon/GARMIN products

- A common theme among new members is that they hear from current SCFLIER Members that this forum is a good way to LEARN and UNDERSTAND Details about the SportCruiser LSA, and so, they join the SCFLIER SportCruiser Forum to LEARN

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

-

Awesome story and excellent planning for your long “trans-continental” Cross Country Adventure in the SportCruiser !

the CRUZ LSA can be an excellent long distance cross country machine, with the proper planning.

Awesome tales of your adventure ....Do you have any pictures en-route to share ?

-

SCFLIER Forum Members !

Happy

New

Year !!!

-

Agree !

Onward and Upward !

D

Get Traffic Advisories by using FAA ATC Flight Following !

-

-

Aaaahh

Facts and Data -

Direct from THE INTERNET

It must be true !

-

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

-

For increased security and protection against forum hackers, the new Website Provider policy on SCFLIER Passwords is:

- 8 or more characters

- mixture of letters and numbers

- mixture of Upper and Lower case

- special characters

- non-dictionary words

If any Member has trouble with their SCFLIER password or logging in, please send me an email to

scflieradm@yahoo.com

with your Display Name (User Id)

And Password problems / desired Password

note that the “Password Reset” for individual SCFLIER Members is NOT functional.

Enjoy SCFLIER !

Admin / DavePilot

-

RTK

Great ideas and comments !

Thanks

Dave

-

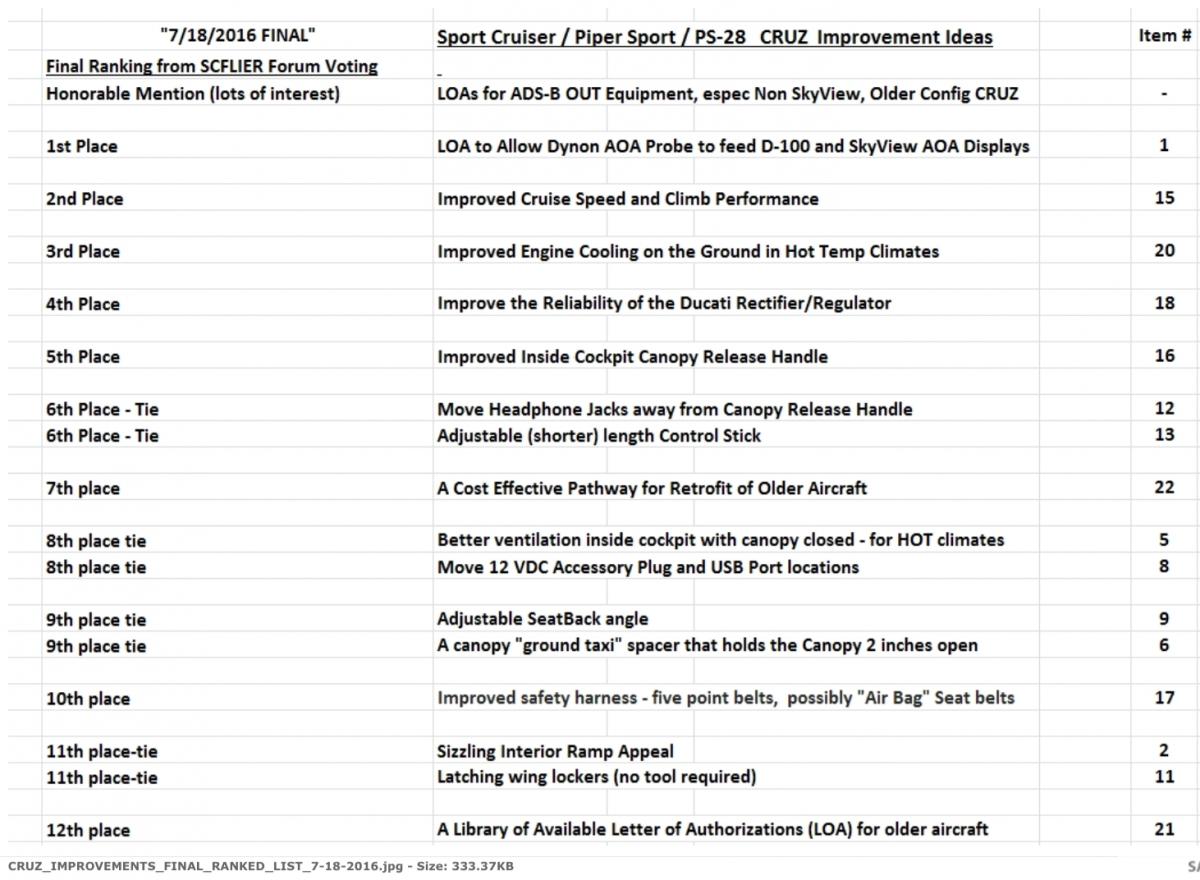

A “status” report on whether Czech Sport Aircraft is “improving” their SportCruiser S-LSA aircraft.

Way back in 2016, we here on SCFLIER generated a List of

”What Improvements Would You Like to See in the CRUZ SportCruiser Aircraft ?”.

Active, Participating SCFLIER Members voted on their “Top 5” choices, and I tabulated the votes and posted this Ranked SportCruiser Improvement List.

The above Ranked Improvement list was hand delivered to CSA Management at Oshkosh 2016 by the Previous Importer, Patrick Arnzen.

For discussion, and I fully expect those that continue to “Dislike” CSA to maintain their Opinions, yet these owners do like very much to fly their CSA/CZAW produced CRUZ LSA Airplanes,

here are my opinions on CSA’s Improvements to date, focused on the Top 5 Items:

- CSA LOA to allow use of the Dynon AOA Probe to feed the D-100 EFIS and SkyView Displays - ZERO RESPONSE from CSA on this proven (by ELSA owners) simple, easy, and useful Safety Oriented Upgrade.

- Improved Cruise Speed and Climb Performance - CSA has researched available engine Upgrade options and chosen the 115 Hp Edge Performance Fuel Injected Upgrade to the existing Rotax 912 engine. An extra 15 Hp can improve Climb performance, and Fuel Injection can improve cold engine starting & fuel economy. The Edge Performance Upgrade would not add as much additional weight to the already heavy SportCruiser as do other Rotax engine choices. Of course Edge Performance does not have the long, proven Reliability history of Rotax engines.

- Improved Engine Cooling on the ground in Hot Temperature climates - CSA has developed a new lower cowling with a larger bottom opening that is said to help cooling during long Taxi Times in Hot Temperature Conditions. Currently, the new lower cowling design is only available for the “non rectangular radiator opening” cowling seen on later model SportCruisers.

- Improve the Reliability of the Ducati Rectifier/Regulator - No specific Ducati Production Control Solder Quality & Stiffer Potting Compound material response from CSA/Rotax/Ducati, although it is possible that the new larger lower cowling opening may help Ducati’s survive longer.

- Improved Inside Cockpit Canopy release handle - No Response from CSA.

- On a Top Request from SportCruiser & PiperSport LSA owners, “provide a LOA for ADS-B OUT Solutions”, CSA has Responded with two options - 1) for those CRUZ aircraft with the taller instrument panel, CSA provided a Service Bulletin for installation of the excellent, legal for use in All airspace world wide, Garmin GTX335 1090 MHz Extended Squitter Transponder with ADS-B OUT (only), and 2) CSA has developed a Letter Of Authorization “Request Process”. I am unaware of any owner testing this new “pay CSA for an LOA” process. And, many SCFLIERs have suggested that the also excellent, less expensive Garmin GDL82 “EASIER ADS-B OUT 978 MHz UAT Solution” would be a great way to retrofit many of the older CZAW produced SportCruisers with an “Easy” ADS-B OUT solution that would ONLY be allowed in USA Airspace below 18,000 ft.

An Internet forum like SCFLIER is a great way to get discussion going on topics important to Pilots Flying the many different models of SportCruisers.

Comments ?

Dave

PS We all have varying opinions on the best way to solve “SportCruiser problems” and IMPROVE an already GREAT LSA Aircraft - The Czech Sport Aircraft SportCruiser/PiperSport.

As your Friendly Admin, It’s perfectly OK to Disagree with another SCFLIER’s ideas, but let’s All

RESPECT

other Member’s Ideas and Comments -

maybe that will help bring out the 98% of our total “Nonparticipating” SCFLIER Members who only “Lurk” in the background, and never Post their OWN opinions and comments on SCFLIER...

I continue to believe that a higher

SCFLIER

MEMBER PARTICIPATION RATE

would increase the useful CRUZ LSA knowledge shared on the SCFLIER FORUM !

-

SCFLIER Forum Members !

-

Stan

thanks for the input on your Zenith 601XLi.

That’s a great looking airplane with an interesting, powerful set of Avionics compared to the CRUZ SportCruiser Avionics mix of that era. Love the Dynon D10EMS - very powerful in a small footprint. Also lots of great Garmin equipment ! Your plan for ADS-B Out and In with the GDL82 and GDL39 Remote should work awesome !

Curious - what’s your empty weight ?

Enjoy !

Dave

-

Stan

welcome to the SCFLIER SportCruiser forum !

and, it is interesting that you fly an AMD USA Factory Built Zenith 601, arguably the CRUZ LSA predecessor design from Zenith, that CZAW was also building in Europe, and which led to the CZAW 2006 OSHKOSH Surprise as the new SportCruiser !

The SportCruiser was similar enough to the Zenith 601 E-AB Kit airplane that Zenith quickly terminated doing business with CZAW in Europe... the week following OSHKOSH 2006.

I believe many SCFLIER SportCruiser Members would love to hear about how your Zenith 601 (2008 AMD factory built CH601XLi-B Zodiac SLSA) flies, and would be interested to learn about any unique characteristics and especially the IFR equipment/Avionics ...

Have you flown a SportCruiser ?

There is a long history between CZAW and Zenith with the two very similar airplanes, the SportCruiser and the Zenith 601 (led to much later the Zenith 650)....

Zenith CH 601 XL

The CH 601 XL was first flown in 1991 as an improved version of the HD developed for the amateur-built market and also for the American Light Sport Aircraft category. The XL features many incremental improvements over the HD, including a new wing design, wing fuel tanks to replace the fuselage tanks of the HD, new landing gear design and a new canopy.

· Zenith CH 650

Modernized version of the 601, with a larger cockpit, a larger canopy with more headroom, swept-back fin and rudder and engine options that include the 120 hp (89 kW) Jabiru 3300, 100 hp (75 kW) Continental O-200 and 100 hp (75 kW) Rotax 912ULS. One hundred had been completed and flown by December 2011.

· Zenith CH 650E

Version for the US light-sport aircraft category.

· Zenith CH 650Ei

Version for the European microlight category, with a gross weight of 472.5 kg (1,042 lb) and a Rotax 912ULS engine of 100 hp (75 kW). Manufactured as a ready-to-fly aircraft by ICP srl in Italy.

· AMD Zodiac XL & XLi

The completed US Light Sport Aircraft compliant version of the XL is the AMD Zodiac produced by Aircraft Manufacturing and Design of Eastman, Georgia, USA. The aircraft is available in two versions, the XL, and the XLi. The XLi is IFR equipped for night flying and instrument flight conditions, while the XL is only equipped for VFR day and night flying.

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

-

Opinion

it is easy to blame all of the Ducati Voltage Rectifier/Regulator failures on the higher temperature at the 2010 - present SportCruiser Ducati mounting location.

And, the late model SportCruiser Ducati Mounting location is, in fact, HOT, especially on the ground with extended taxi times.

But if one looks closer at the details, Ducati has produced Rectifier/Regulator units with low quality soldered electrical connections to their internal circuitry.

And while low quality solder joints MAY “work OK” in cooler conditions, these lower quality solder connections will eventually FAIL when subjected to heat and vibration .

Also, about 2009, Ducati changed the recipe for their internal “potting compound” that reduces electrical components inside the Ducati from vibrating away from the circuit board,

to a new black in color potting compound that gets significantly “looser” when hot.

This new Ducati potting compound allows the internal electrical components to vibrate against the poor quality solder joints, especially when hot. And eventually the internal Ducati electrical connections will break free.

This explains why “pre - 2009” green colored, stiffer when hot, older Ducati potting compound filled regulator units may last longer than the post 2009 Ducati units.

Military Electronic equipment manufacturer’s use a pre-delivery Quality Control test called ESS, Environmental Stress Screening, where production units are subjected to accelerated levels of heat and vibration in a factory test chamber to ferret out production quality control problems like poorly soldered internal electrical connections. Low quality solder connections are found and fixed before delivery with this ESS technique to ensure longer term reliability of electronics for the very demanding Military temperature / vibration requirements.

Commercial electronic equipment producers (like Ducati) oftentimes do not perform any kind of pre-delivery Environmental Stress Screening Quality Control tests on their production units.

The SportCruiser designers can be “blamed” for mounting the Ducati in a hot location, and for arranging the post 2009 SportCruiser installed Ducati’s heat sink fins perpendicular to the cooling air flowing DOWN the engine firewall. A very inefficient heat transfer cooling fin arrangement - the internal Ducati electrical components get even hotter with the first, top heat sink fin blocking most of the cooling air.

But if one looks further at the root cause of Ducati failures, the Ducati Rectifier /Regulator has had documented production solder quality control issues, and when coupled with a “spongy, looser” (new since 2009) black colored potting compound, the low quality electrical solder connections inside the Ducati will come loose over Time.

There are PLENTY of documented Ducati Rectifier/Regulator failures for Rotax to admit, and then to demand their long time Ducati supplier to investigate and solve, providing a better, more RELIABLE DC Voltage regulator component for their excellent Rotax 912 engine’s Internal Alternator.

Of course the SportCruiser Czech Sport Aircraft manufacturer can be blamed easily for mounting a known “heat sensitive” Ducati electrical component in a hot environment.

But the current design, as produced Ducati Rectifier/Regulator would not survive long in most AUTOMOTIVE specified Temperature/Vibration Environments.

And yet we fly this Ducati Voltage Rectifier/Regulator at night In an AIRPLANE, when our cockpit Avionics and Instrumentation, NAV/Strobe lights, Transponder, ADS-B OUT equipment (if equipped) and Com Radio ALL depend on RELIABLE 12 volt DC power.

Improvement ? Options :

1) Ducati production control could Look a little closer at their production line’s solder quality, and change back to the older “green color” stiffer internal potting compound to help units survive longer under heat and vibration.

2) Ignore the Ducati production quality / design problems and we can simply blame the Czechs’ Hot Mounting location for Ducati failures in late model (since 2010) SportCruisers.

Dave

PS

or,

Option 3), a third alternative, is for E-LSA Experimental SportCruiser aircraft owners, to buy a Form-Fit-Function replacement Rotax Rectifier/Regulator unit Built by Silent-Hektik. A more sophisticated 12 Volt DC Regulator electrical design with higher build quality, and more robust heat sink fins for reliable use in a hot environment.

Details on Investigations of Failed Ducati Units’ Solder Production Quality Control and Potting Compound Production “Stiffness” Changes. (New ~ 2009) that Exacerbate the Ducati Solder Quality Issues under Heat and Vibration.

Documented here on SCFLIER, and also on the Vans AF RV-12 Forum (Mike M).

Poor Ducati Internal Solder Quality Examples from analysis of a failed unit:

Measurement of the decreased stiffness of the Black Color, New since ~ 2009 Ducati Internal Potting compound

Examples of poor solder quality internal electrical connections inside a failed Ducati unit

Example of failed internal Ducati Electrical Connections due to Poor Solder Factory Quality Control - on the main SCR DC Regulator control’s switching components

Standard Electronic Equipment and Component Temperature Ranges:

Commercial (the lowest grade) : 0 °C to 70°C (158 deg F), and some manufacturers also use 85 °C (185 deg F) for the high temperature side of "Commercially" Rated Parts.

Note that the Rotax recommended Maximum Temperature For the Ducati Rectifier / Regulator is 80 degrees C, 176 degrees F

Industrial : −40 °C to 100 °C. 212 deg F on the high temperature side

Automotive : −40 °C to 125 °C. 251 deg F on the high temperature side

Military (the best, most Reliable grade) : −55 °C to 125 °C. 251 deg F on the high temperature sideESS - Environmental Stress Screening

https://en.wikipedia.org/wiki/Environmental_stress_screening

-

SCFLIER Forum Members !

-

SCFLIER Forum Members !

SCFLIER Forum Activated Members Count

in Forum Information & News from the Admin

Posted

SCFLIER Forum Members !

We may reach 500

SCFLIER Members in July ! ? ! 2020